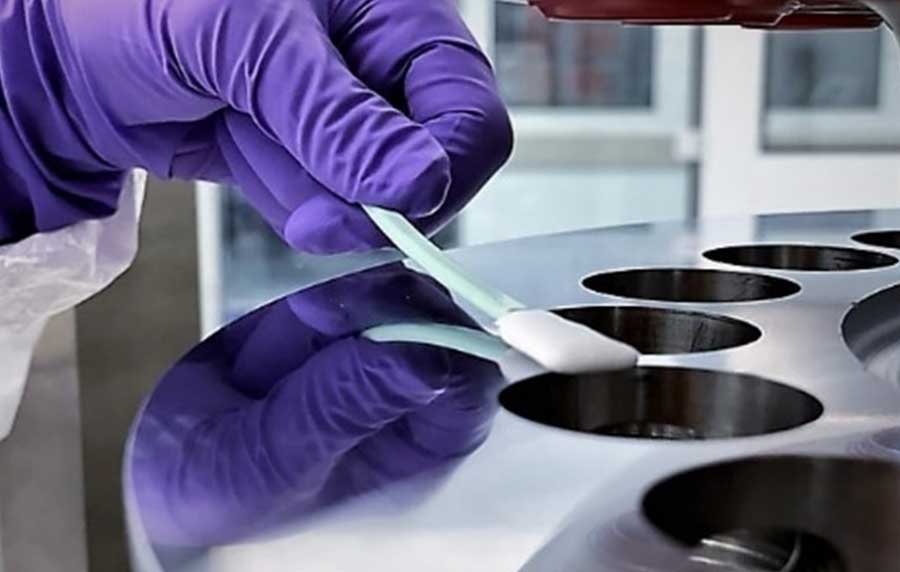

Cleaning validation is a critical process that can be utilized not only in pharmaceutical and chemical industries but also in the food industry to ensure that plants and equipment are adequately cleaned between uses to prevent cross-contamination between different products and contamination derived from the use of cleaning and biocidal products.

Cleaning validation involves a series of activities, including defining cleaning criteria and protocols, conducting analytical tests to confirm the removal of product and/or chemical residues, and documenting the results obtained.

Why It’s Important

Cleaning validation in a food plant is extremely important for several reasons:

- Product safety: The presence of cleaning agent residues in a plant can contaminate the product, compromising its safety and quality.

- Prevention of contaminations: Inadequate cleaning of plants can lead to chemical contaminations of products, posing potential health risks to consumers. Cleaning validation helps prevent these contaminations by ensuring that plants are effectively cleaned.

- Maintenance of process efficacy: Proper cleaning of plants ensures that they function correctly and that production processes are carried out efficiently and effectively. Cleaning validation helps maintain the integrity of the production process.

- Cost reduction: Effective cleaning reduces the risk of contamination and product losses, helping to reduce production and quality control costs.

Cleaning validation is not just a recommended practice, but a necessity to ensure product safety, prevent chemical contaminations, and maintain process effectiveness.